Deep-Sea Drilling Expertise

Gunther Consults & Industrial solutions delivers cutting-edge offshore solutions for the most challenging marine environments. Our expertise includes:

- Subsea platform design and engineering

- Deep-water drilling system installation

- Corrosion-resistant marine construction

- Offshore safety and risk management

- Environmental impact mitigation

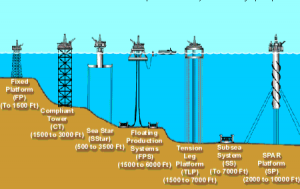

We handle Fixed Platforms

Template (jacket) Platform:

These structures are used in waters of moderate depths (up to 400m). They are the structures that you would typically see in the Persian Gulf, Gulf of Mexico, Nigeria and California shorelines. On a jacket platform, the working platform is generally sitting above the water line and the risers are lowered into the ground. The “Jacket” is a structure built around the risers to provide a protective layer around the pipes.

On these structures ROVs such as the DTX2 can be used to inspect the underwater infrastructure when the structure is not too deep. Units such as the DTG2 can be used to inspect onboard water tanks.

Floating Production Systems

These structures are essentially semi-submersible drilling rigs as discussed above but in addition they contain petroleum production equipment along with platform drilling equipment. Ships can also be used as floating production systems. They are kept in place with large, heavy anchors or with similar technology to that of drillships. With these structures, the wellhead is actually attached to the seafloor instead of on deck and is transported via risers to the production facilities on-board. Mini ROVs can be used to inspect the bottom of the hulls and again on-board equipment.

Tension Leg Platforms

It consists of a floating rig, much like the semi-submersible platforms but also has long, flexible legs that are attached to the seafloor and run up to the platform itself. The legs allow for significant side-to-side movement to take the pressure of waves off of the structure, but offers very little vertical movement. These structures can be used in waters as deep as 7000 feet. Mini-ROVs can be used efficiently by inspecting the inner hulls of the structures.

Seastar Platforms

These are essentially miniature tension leg platforms. With floating hulls and tension legs used to hold them in place, they are generally used in smaller deep-water reservoirs when it is not economically efficient to build a larger structure. Mini-ROVs can be used to inspect the inner and outer areas of the hulls that are filled with water.

ROVs and Offshore Platforms

In addition to the 9 rig and platform structures discussed above there are also structures like Subsea systems, Spar platforms and Compliant Tower Platforms that are used in much deeper water and typically do not have many underwater uses for mini-ROVs. That being said most rigs do have water tank and cooling tank components that can be effectively inspected with a mini-ROV.